|

On Thursday, September 12, WITA will host a panel at the WTO Public Forum in Geneva, Switzerland to explore how the WTO can help foster a circular economy for critical minerals. Find more information here and below.

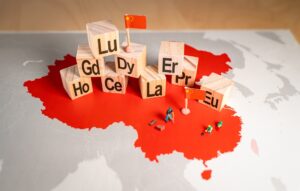

In 2019, at the height of the trade war with the United States, Chinese President Xi Jinping visited a rare earth magnet factory in Jiangxi Province. At the time, the visit was interpreted as “muscle flexing” by China’s leader to remind Washington of its dependence on Beijing for the supply of rare earths. Rare earth elements (REEs) – a group of 17 critical metals – are indispensable components in military defense systems, consumer electronics and renewable energy technologies. Despite more than a decade of sustained efforts by Western countries and companies to loosen China’s grip, Beijing, by far remains the top player in the REE global mining, processing and refining sectors.

Xi’s visit also conveyed a broader Chinese goal in the Rare Earths sector that goes beyond mining: maintaining leadership in the downstream industrial supply chains of processing, refining, and magnet production. While the semiconductor war gets more attention, there is another tech battle underway in the rare earths supply chains as China continues to tighten its control over what it calls a “state resource” and its supporting technologies.

The Western rush to build China-free supply chains with both upstream and downstream industries is masking the bigger technological challenge of establishing a sustainable processing capacity. Given the stakes, a targeted approach is required to solve the processing tech puzzle through investments in R&D, international partnerships, and diffusion of alternate methods.

Rare Earths, Rarer Tech?

In 1992, while visiting Baotou, Inner Mongolia, one of China’s biggest rare earth mines, Chinese leader Deng Xiaoping famously said, “The Middle East has oil, China has rare earths.” He was referring to the country’s resource endowment of over 30% of the world’s reserves. But unlike the Middle Eastern oil producing countries who primarily drill and export crude, China built an entire ecosystem around the rare earths, from mineral production and processing to manufacturing finished products, and most importantly, rare earth magnets.

China has maintained leadership at every step up the ladder. Though its global production share dipped from a staggering 97% in 2011 to around 70% in 2022, it still controls over 85% of processing capacity. China has an effective monopoly over processing major heavy rare earths – Dysprosium (Dy) and Terbium (Tb), and Light Rare Earths – Neodymium (Nd) and Praseodymium (Pr).

Environmental impact is often cited as one of the main reasons for China’s emergence as a rare earth powerhouse, but the technological aspect is less discussed. From 1950 to October 2018, China filed over 25,000 rare earth patents, surpassing the US’ 10,000. Over decades, Chinese engineers perfected the solvent extraction process to refine REEs which plays a critical role in ensuring China’s primacy. Though the technology originated in the United States, environmental and regulatory concerns made domestic rare earth development unfeasible.

|